Ultra-thin grain oriented electrical steel strip: GTseries

More than 30 years of use for reactors in the power and renewable energy fields

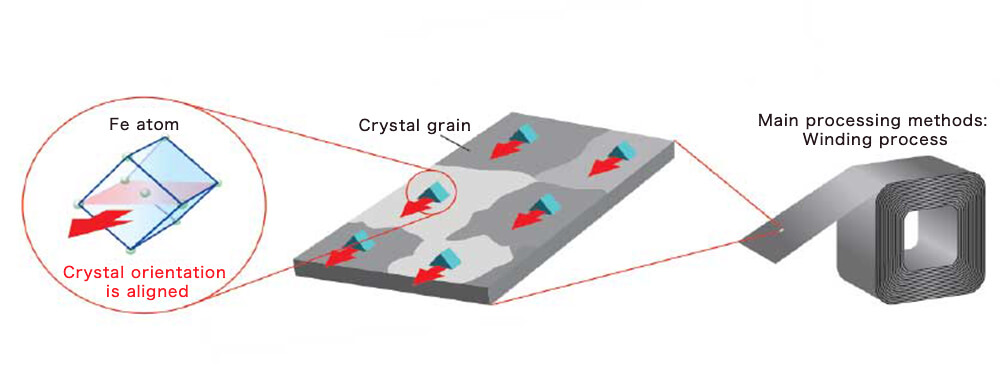

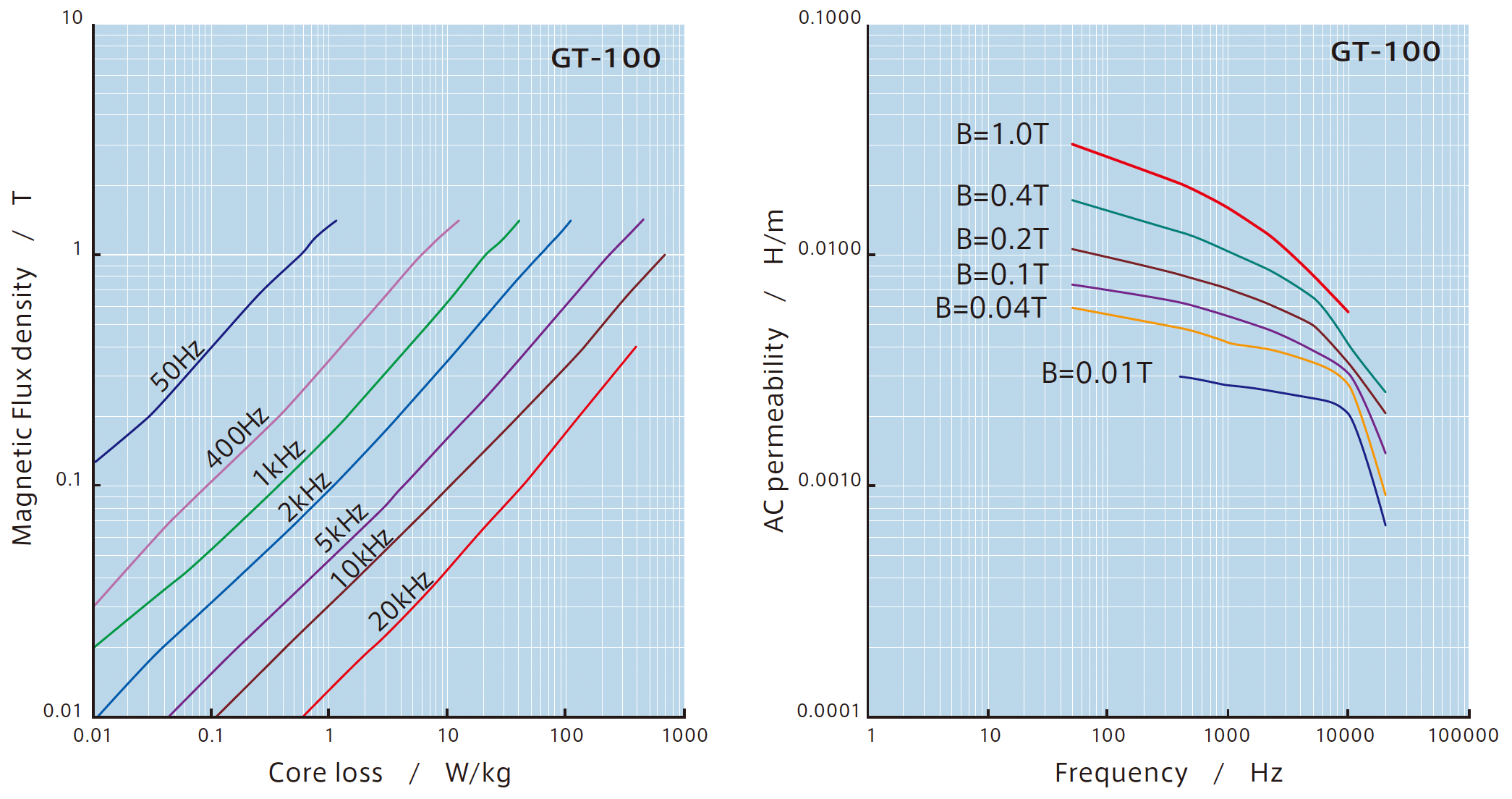

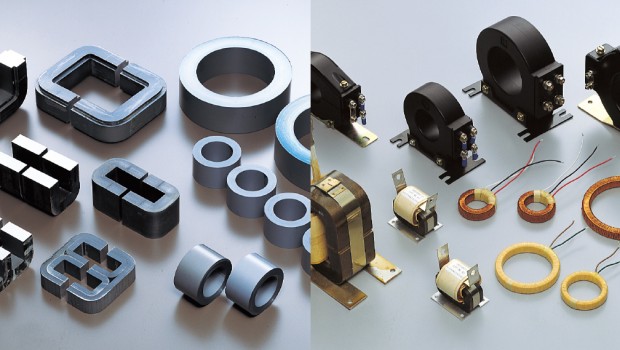

As the magnetic properties are aligned in the longitudinal direction of the steel strip, they are mainly used as wound cores. The thin thickness enables extremely low iron loss in the high rotation range and the high magnetic flux density compared to other materials make it an ideal material for cores in high-frequency reactors, high-frequency transformers, etc.

Application example

-

Electricity

-

Renewable energy, UPS

-

Welding machine

-

Lighting equipment

Features

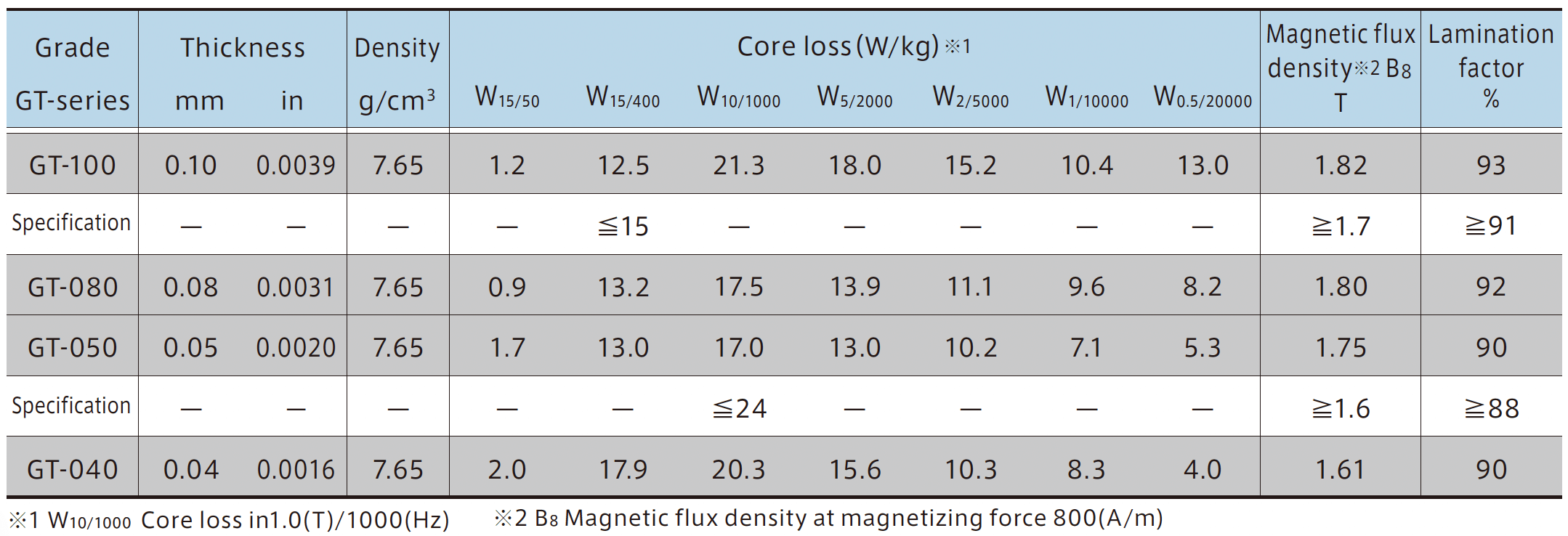

- Low core loss

- The eddy current can be suppressed by thinning thickness, and the iron loss can be reduced.

- Downsizing

- Contributes to downsizing of reactors, etc. due to its high magnetic flux density.

- Optimal usage range

- Higher magnetic flux density than other materials at operating frequencies of 400 Hz to 40 kHz, enables downsizing of reactors, etc.

- Insulation coating

- The excellent insulation resistance enables to take full advantage of the material properties. Furthermore, the high heat resistance temperature allows a stable film to be maintained even at high temperatures (up to 850°C).

- Raw material

- The ultra-thin electrical steel strip is made from Fe-3% Si steel (raw material from NIPPON STEEL) and is a highly reliable electrical steel strip has been used for over 50 years.

Catalog Download

For customers who would like to receive our product catalog

Please fill in the information from the “Download Application” below and submit your request.

You will receive an auto-reply e-mail with a URL to download the product catalog PDF.